Waterproof plywood - DIY

Waterproofing plywood, is it possible? Yes, protecting plywood against moisture is possible, but before we jump into the solution on how to use plywood in damp or outright wet environments, it is useful to take a brief look at what plywood actually is, how it is made, and why it is a problem when it gets wet.

What is plywood?

Plywood is sheet material that consists of multiple layers – always an odd number – of wooden veneer. These veneers are glued together crosswise. The term multiplex is used for boards having 5 layers or more. Plywood has the same composition, but consists of only 3 layers. The material is made by drying the veneers first. When the material has the correct moisture level, it is glued and pressed together at a high temperatures.

The glues used are polycondensative adhesives that are commonly used for load-bearing timber structures. Because a multiplex layer consists of several layers, it can also be used with different kinds of wood, such as birch wood, mahogany or okoumé. Often, the outer layers that are exposed to the atmosphere, are of the more expensive types of wood, and the inner layers are made from cheaper wood. At the end of the production, the large plates are cut to size (or standard sizes) and possibly sanded.

Thanks to this way of construction, multiplex has a number of advantages as a construction material. It uses wood efficiently because also lower quality parts, or types of wood, can be used. In particular for the inner layers. Because of the symmetrical composition with different layers – from the middle layer both sides always are the same type of wood – plywood exhibits less adverse effects than solid wood. In some directions, plywood is even stronger than normal wood. In comparison with MDF boards, multiplex is stronger, lighter and has almost no creep.

Multiplex is used for a large number of applications, often with added layers tailored for particular applications. For example, there is multiplex for use in the construction of buildings. Plywood used in visible applications can have a layer of veneer, and you also have plywood for concrete molds. There is also special plywood for use in aircrafts and extra strong, bullet-resistant plywood. There is even multiplex with a single lead layer, to block X-ray radiation in hospitals.

Does waterproof plywood exist?

Plywood is composed of veneer sheets, and because untreated timber is not waterproof, plywood also is not. However, plywood WBP is available. Plywood WBP stands for Water Boiled Proof and is suitable for use in humid environments. But in fact, this only indicates the type of adhesive is suitable for use in a wet environment, without having the glued layers of the plywood come apart. However, the multiplex itself is not protected, and the layers of wood, or veneer layers, can still be affected by moisture and water. Whether the plywood itself can handle moisture well, mainly depends on the types of wood used. The glue of WBP is waterproof, the veneers itself probably not.

Fortunately, there is a solution, just like solid wood, multiplex and plywood can be protected from moisture. The solution is called Woodcon.

With Woodcon you can waterproof plywood

Woodcon makes timber, and also the timber layers in plywood, water-repellent. There is no discoloration of the wooden surface, and the texture of the wood remains completely intact. Woodcon creates a water-repellent coating, but without the typical wet, glossy look that occurs in many other wood preservatives. Woodcon reinforces the natural, rustic appearance of the wood.

The effectiveness of Woodcon can be contributed to the fact that it does not create a separate layer on the plywood, such as other wood protection solutions, but it actually impregnates the wood. The wood protective product Woodcon creates a coating in and around wood and nestles inside the fibers. Woodcon makes wood water-repellent as a whole, and not only produces a water-repellent layer on the outside. This automatically means Woodcon cannot get detached from the wood like other products. Paint, varnish and stain may flake, crack, burst, or peel, and thereby loosen the timber. When water is able penetrate the wood, it can begin or continue its destructive work. Woodcon creates a transparent water-repellent layer in and on the wood surface, and will never peel or break off. Because Woodcon fixes itself around the wooden fibers, it not only protects the wood against moisture, but it also prevents damage to the plywood by wood fungus, algae and moss. Even the intrusion of termites and woodworm is being stopped by Woodcon.

Woodcon is not only the perfect solution for waterproofing plywood and timber. After treatment with Woodcon, even cane and rattan can be used in a wet or damp environment. So rattan garden furniture, thatched roofs, and any other cane or rattan applications you want, Woodcon allows for it.

How do you waterproof multiplex with Woodcon?

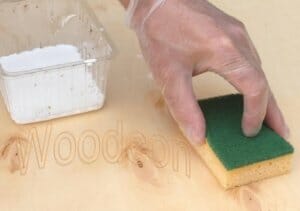

Woodcon can be easily and safely used by any do-it-yourselfer. It is nontoxic and not damaging to flora and fauna. Woodcon is non-flammable, and it cannot explode. Rather, Woodcon even has a fire-retardant effect on wood and plywood. Woodcon is available in packs ranging from 1 to 25 liters. depending on the porosity of the wood, 1 liter is usually sufficient for wood or plywood with a surface area of 88 ft², depending on the porosity of the surface. The product can be easily applied with a paint brush, paint roller, sponge or low pressure spray. Woodcon waterproofs wood and plywood.

Woodcon

- Woodcon makes every wood-surface waterproof and water-repellent without discoloring or changing the surface of the wood.

- 15 year guarantee

- Depending on the porosity of the wood, 1 liter is sufficient for an average 88 ft²

- Available in 1 / 2,5 / 5 / 10 / 25 Liter.